At the AMPER 2025 exhibition, we presented our innovative solutions that push the boundaries of automated quality inspection of printed circuit boards (PCBs). At our booth, we showcased three key products in this field:

1. Video Magnifier

Our video magnifier solution offers a cost-effective approach to visualizing fine details on PCBs. An operator who previously worked with a microscope with a limited field of view can now, thanks to a detailed image on a 4K monitor, see every micro detail. This approach not only increases inspection accuracy but also significantly speeds up defect identification.

2. Inspection Table – Automated Component Placement Control

The second exhibit was an inspection table designed for automated checking of component placement on boards. This system is built to provide fast and reliable inspection in demanding industrial environments. High-quality components and precise settings ensure that every inspection step is carried out with maximum accuracy.

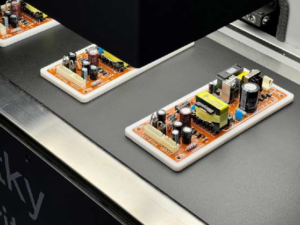

3. Online Conveyor Solution – Real-Time Inspection

The last exhibit was an online solution for PCB inspection directly on the production line. This system uses specially designed lighting and real-time digital analysis. The result is increased production efficiency and 100% quality control, minimizing the risk of faulty processing.

Our solution for 100% automated PCB inspection combines state-of-the-art software with top-class hardware components, allowing us to significantly outperform conventional systems.

Software Snapshot Analyzer:

Efficient Data Management and Export:

All tests and results are automatically recorded, with the system enabling export of debug images and results (e.g., into CSV files). This approach ensures a high level of transparency and supports further analysis and product traceability.

Fast Integration into the Production Process:

Thanks to the flexibility of Desktop and Inline versions, the system can be easily and quickly integrated into existing production lines. Immediate operator alerts upon detecting deviations ensure that errors are caught in time and production never compromises on quality.